Precision Milling

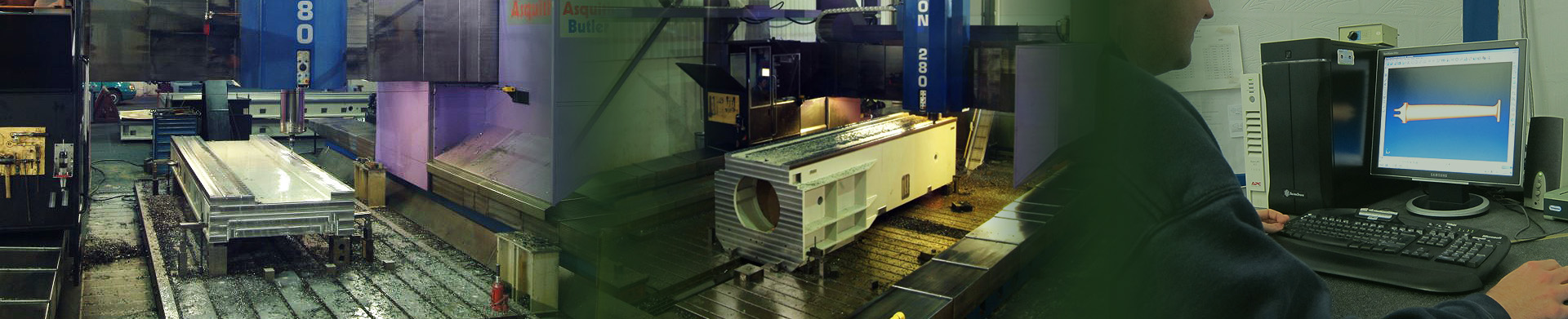

Forths' sub contract machining facility consists of two state of the art Asquith Butler CNC Gantry Milling machines contained within an interconnected temperature controlled manufacturing cell.

These machines combine to allow component part machining to a maximum length of 9.5 metres, a width of up to 4.5 metres and an overall height of 1.7 metres.

All machines are in-house laser calibrated on a scheduled basis, allowing full control over the range of permissible positional error in any linear direction. This calibration is carried out to a level of accuracy that is commensurate with the precision of tolerance required by our customers.

Our Gantry Mills have up to 5-axis machining capability, all feature Fanuc 15i-M control systems and RMP60 Renishaw radio probes, with these factors combining to allow complete versatility and flexibility of our production resources.

Forths' production experience covers a wide range of component constructions such as forgings, castings, fabrications, composite structures and raw plate up to 20 tonnes.

Similarly the range of materials with which we have experience of machining covers mild steel, stainless steel, aluminium, titanium, cast iron and high speed steel.

We have fastidiously worked over a considerable period to diligently and precisely hone our craft of ultra-high precision machining of component parts with exacting tolerances in regard to straightness, flatness and squareness, as being principally associated with Europe's most prestigious Machine Tool builders.